Types of CNC control systems

CNC control systems

CNC, which stands for Computerized Numerical Control, is a method for automating control of machine tools, by using the software embedded in a microcomputer attached to said tool. CNC is commonly used in mills, lathes, grinders, lasers and routers. It can be also used in order to control tools such as production belts and welding, electronic assembly, folding products and filament-winding machines. CNC helps to improve and modernize production process, allowing the company to increase the profit.

Types of CNC Controllers

Currently there are three types of CNC controllers: motion type, loop control, and axis type.

Motion Type CNC Controllers

With motion type CNC controllers, the tool is positioned in a strictly defined point in relation to the workpiece. The speed and path of the tool is irrelevant, however, to speed up the process and make sure it is fully collision-free, it is recommended to maintain the straight line and maximum speed. Motion type CNC controllers are the simplest and most common. They are often used in machines where it is essential to position the tool over the axis of a hole, such as drills, boring and perforating machines.

Loop Control CNC Controllers

Loop control CNC controllers allow movements at a certain speed and along a certain path, which is always parallel to the specific coordinate axis in the previously specified plane. Loop control CNC controllers can be divided in two categories:

- open-looped, where the instructions and programs are transmitted to the controller through the input device,

- closed-loop, where the feedback is gathered from the control system.

Axis Type CNC Controllers

Axis type CNC controllers allow for any movement – aside from straight lines also various bevels, arcs and curves. The vast variety of contours can be obtained thanks to the cooperation of two or more motors acting as feed motion drives. Depending on the number of controlled axes, three kinds of axis type CNC controllers can be distinguished:

- two-axis control (2D), in which the tool can move along an arc of a circle or an ellipse,

- two and a half axis control (2½D), in which the tool can perform movements on different planes of the X/Y, X/Z and Y/Z coordinates (it needs to be noted, however, that no more than two axes can be controlled in a given plane at the same time),

- three-axis control (3D), in which the tool can perform spatial movements.

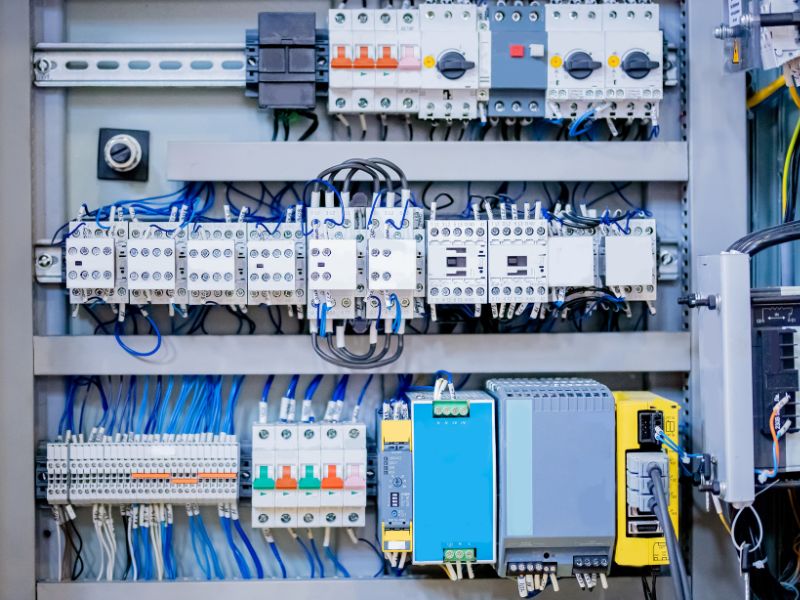

Elements of CNC Controllers

Regardless of the type, a CNC controllers consist of four basic elements: power supply unit, machine control unit, processing equipment and circuitry protection system.

- Power Supply Unit

The most basic element of a CNC Controller is a power supply unit. In a lot of CNC controllers there’s a need for dual supply – low-voltage communication line and a steady motor supply, with the latter providing energy for the activities such as moving, drilling and cutting, among others.

- Processing Equipment

The processing equipment is a unit of a CNC that transforms a workpiece into a finished product. It transmits necessary data to drive the tools.

- Machine Control Unit

The machine control unit in a CNC controller serves as an interpreter, translator and executive force for the codes received from the machine interface software. It is further divided into parts such as I/O ports, cache memory, and circuitry protection systems.

- Circuitry Protection System

The circuitry protection system is a part of a CNC controller containing a breakout board to isolate the signals received from the computer and to distribute them to the proper drives. It also contains fuses used to protect equipment in case of faulty wiring or voltage surges, spikes and shorts.

Accessories for CNC control systems

Some of the CNC systems are integrated with accessories, such as:

- CAD – computer-aided design software,

- CAM – computer-aided manufacturing software,

- ERP – enterprise resource planning,

- EAM – enterprise asset management software.

These accessories for CNC control systems can speed the process of programming the microcontroller unit, facilitate operational intelligence processes and, additionally, improve plant performance and maintenance.